Emial Us :

sales2@hjauto.com.cn

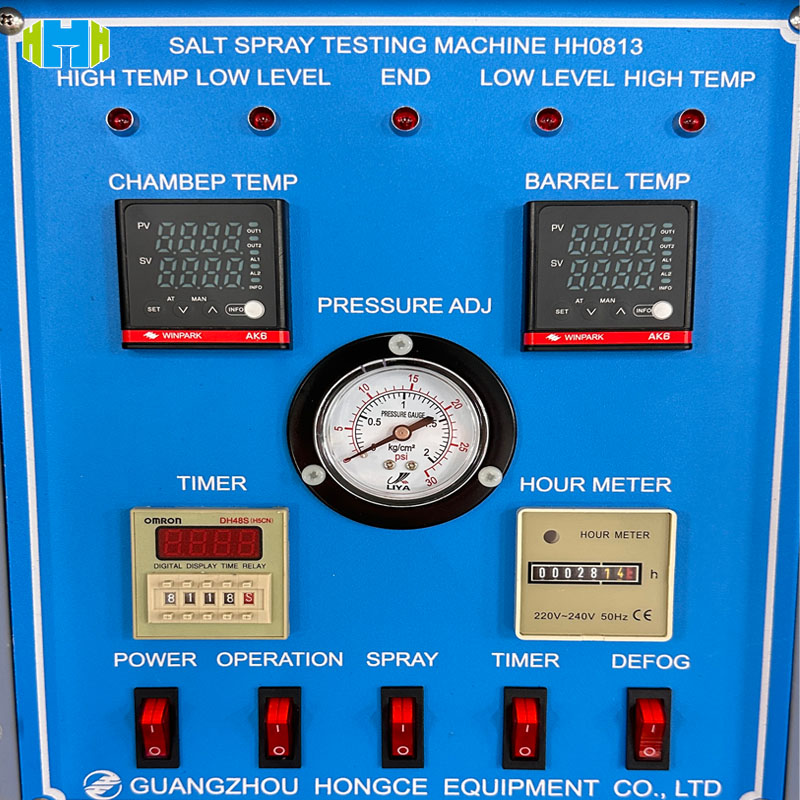

غرفة اختبار رش الملح HH0813 مصممة خصيصًا لاختبار مقاومة المواد للتآكل! بصفتها شركة تصنيع معتمدة، تستخدم HongCe براعتها في ابتكار معدات اختبار بيئي عالية الدقة، تدعم اختبارات التآكل الدوري متعددة المعايير، وتغطي قطاعات مثل الصناعة والإلكترونيات والسيارات. بفضل التحكم الذكي في درجة الحرارة، وفوهات منع التبلور، والتصميم الملائم، تصمد منتجاتكم أمام التحديات البيئية القاسية وتحافظ على جميع التزامات الجودة!

رقم الصنف :

HH0813النظام (موك) :

1 setدفع :

Negotiatableأصل المنتج :

ChinaPayment Method :

5 sets per monthغرفة اختبار رش الملح HH0813 لاختبار التآكل الدوري وفقًا لمعيار ASTM B117، معدات الاختبار البيئي

مقدمة المنتج:

في ظل المنافسة العالمية الشرسة اليوم، تُعدّ مقاومة المنتجات للتآكل مفتاحًا لكسب ثقة السوق. تعتمد غرفة اختبار رش الملح HH0813، التي تُصنّعها شركة HongCe، على "الدقة والموثوقية والكفاءة"، حيث تُحاكي بيئات مُعقّدة مثل رش الملح والرطوبة والحرارة والجفاف، وتُقيّم بشكل شامل مقاومة الطلاءات والطلاء الكهربائي والمعادن والمكونات الإلكترونية للتآكل. سواءً كان الأمر يتعلق باختبار تقادم رش الملح لقطع غيار السيارات أو التحقق من مقاومة الصدأ للمنتجات الإلكترونية عالية الجودة، يُمكن لهذه الغرفة توفير بيانات دقيقة تُساعدك على اكتشاف العيوب المُحتملة مُسبقًا وضمان متانة المنتجات في البيئات القاسية.

المعايير المرجعية الدولية:

ASTM B117-2023: مواصفات اختبار رش الملح القياسية، المطبقة على الطلاءات والأجزاء المطلية بالكهرباء وما إلى ذلك.

ISO 9227:2022: طريقة اختبار رش الملح لاختبار التآكل في البيئة الاصطناعية.

GB/T 10125-2021: المعيار الوطني الصيني، المعادل لمتطلبات اختبار رش الملح الدولية.

DIN 50021: المعيار الصناعي الألماني، عملية اختبار التآكل الدوري.

JIS Z 2371:2015: المعيار الصناعي الياباني، تقييم تحمل رذاذ الملح للمنتجات الإلكترونية.

استخدام المنتج:

المجال الصناعي: التحقق من مقاومة التآكل لأجزاء السيارات ومواد الطيران وطلاء السفن.

الصناعة الإلكترونية: اختبار مقاومة الصدأ للوحات الدوائر المطبوعة والموصلات والأغلفة.

اختبار المنتجات الاستهلاكية: تقييم الشيخوخة الناتجة عن رش الملح على سطح الأجهزة المنزلية، والأدوات المعدنية، والمعدات الخارجية.

مؤسسات البحث العلمي: تطوير المواد الجديدة، وتحسين عملية مكافحة التآكل، وأبحاث التكيف البيئي.

المعايير الفنية:

| نموذج | HH0813 | HH0813A | HH0813B | HH0813C | HH0813D | ||||

| حجم الغرفة الداخلية (مم) | 600*450*400 | 900*600*500 | 1200*800*600 | 1600*800*600 | 2000*800*600 | ||||

| حجم الغرفة الخارجية (مم) | 1070*600*1180 | 1410*880*1280 | 1900*1180*1600 | 2300*1180*1500 | 2700*1180*1600 | ||||

| درجة حرارة غرفة الاختبار | طريقة اختبار المياه المالحة (NSS ACSS) 35 درجة مئوية ± 1 درجة مئوية / طريقة اختبار مقاومة التآكل (CASS) 50 درجة مئوية ± 1 درجة مئوية | ||||||||

| درجة حرارة برميل الضغط | طريقة اختبار المياه المالحة (NSS ACSS) 47 درجة مئوية ± 1 درجة مئوية / طريقة اختبار مقاومة التآكل (CASS) 63 درجة مئوية ± 1 درجة مئوية | ||||||||

| درجة حرارة الماء المالح | 35 درجة مئوية ± 1 درجة مئوية 50 درجة مئوية ± 1 درجة مئوية | ||||||||

| سعة غرفة الاختبار | 108 لتر | 270 لترًا | 480 لتر | 800 لتر | 1440 ل | ||||

| سعة خزان المياه المالحة | 15 لترًا | 25 لترًا | 40 لترًا | 40 لترًا | 40 لترًا | ||||

| تركيز الملح | محلول كلوريد الصوديوم تركيز 5% أو أضف 0.26 جرام من كلوريد النحاس (CuCl2 2H2O) لكل لتر من محلول كلوريد الصوديوم بتركيز 5% | ||||||||

| ضغط الهواء المضغوط | 1.00±0.01كجم/سم² | ||||||||

| كمية الرش | 1.0~2.0مل/80سم²/ساعة (يتم جمعها لمدة 16 ساعة على الأقل، مع أخذ المتوسط) | ||||||||

| الرطوبة النسبية لغرفة الاختبار | أكثر من 85% | ||||||||

| قيمة الحمض PH | 6.5~7.2 3.0~3.2 | ||||||||

| وضع الرش | رش قابل للبرمجة (بما في ذلك الرش المستمر والرش المتقطع) | ||||||||

| تلبية المعايير | JIS، ASTM، CNS | ||||||||

| مزود الطاقة | 120 فولت، 60 هرتز | ||||||||

أشياء الاختبار وعناصر التفتيش:

أشياء الاختبار: الطلاء المعدني، الطلاء العضوي، أجزاء السيارات، المكونات الإلكترونية، الأجزاء البلاستيكية، إلخ.

بنود التفتيش: معدل التآكل بسبب رش الملح، التصاق الطلاء، التآكل الكهروكيميائي، مستوى الصدأ، تقييم متانة المواد.

صور تفصيلية:

ساعات العمل لدينا

الإثنين 21/11 - الأربعاء 23/11: 9 صباحًا - 8 مساءً

الخميس 24/11: مغلق - عيد شكر سعيد!

الجمعة 25/11: 8 صباحًا - 10 مساءً

السبت 26/11 - الأحد 27/11: 10 صباحًا - 9 مساءً

(جميع الساعات بالتوقيت الشرقي)