Emial Us :

sales2@hjauto.com.cn

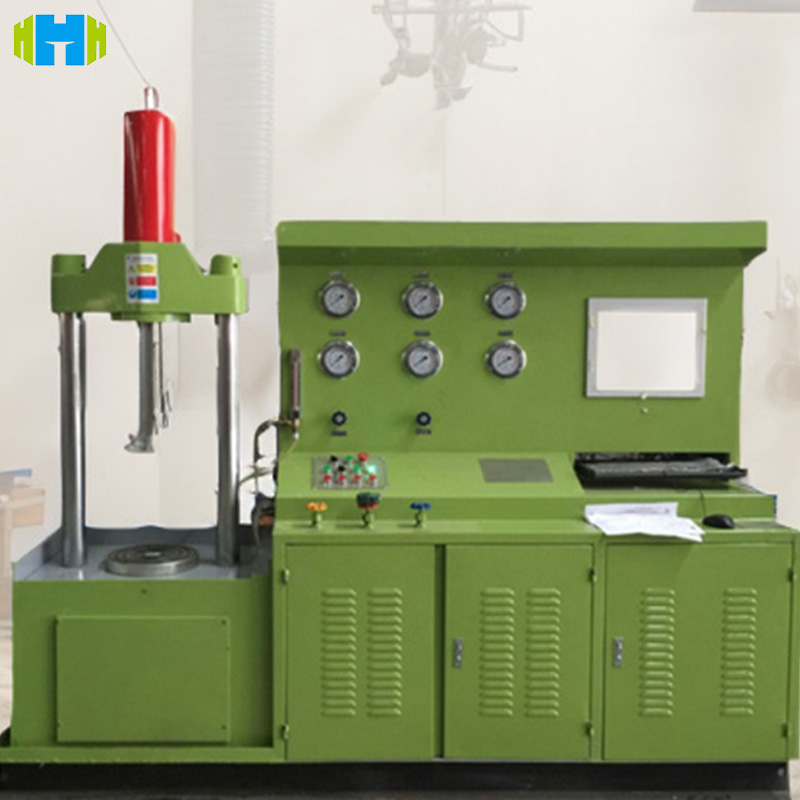

جهاز WPT-7 هو جهاز اختبار ذكي مصمم للصمامات الرأسية ومقاييس التدفق. يدعم الجهاز اختبار تدفق يتراوح بين 0.1 و200 متر مكعب/ساعة (دقة ±0.3%) واختبار ضغط يتراوح بين 0 و40 ميجا باسكال، ويدمج أكثر من 15 اختبارًا لمؤشرات القلب، مثل خصائص التدفق، والختم، ومقاومة الضغط. يتميز الجهاز بهيكل معياري رأسي، ويمكنه استبدال معدات DN25-DN300 بسرعة في غضون 10 دقائق، وهو مزود بشاشة لمس مقاس 10 بوصات ونظام تحكم ذكي PLC، ويُصدر تقارير اختبار تلقائيًا تتوافق مع معايير ISO 5167 وAPI 6D. وهو مناسب لأبحاث وتطوير المعدات، وفحص جودة الإنتاج، واختبارات الاعتماد في صناعات المياه والبتروكيماويات والطاقة.

رقم الصنف :

HONGCEالنظام (موك) :

WPT-14دفع :

Calibration certificate(cost additional)أصل المنتج :

CHINAPayment Method :

L/C, T/TRegular Packaging :

Plywoodمقياس تدفق الصمام الرأسي، منصة اختبار ذكية، كشف تدفق عالي الدقة، تكيف كامل العيار، معيار ISO5167

مقدمة المنتج

يعيد WPT-7 تعريف معيار التحقق من أداء الصمامات/مقاييس التدفق من خلال الكشف الرأسي الفعال وتقنية القياس والتحكم الذكية:

1. الهيكل الرأسي والكشف الفعال

2. اختبار الأداء متعدد الأبعاد

كشف التدفق:

النطاق 0.1-200 متر مكعب/ساعة (دقة معايرة مقياس التدفق الكهرومغناطيسي ± 0.3%)، يدعم المياه النظيفة والنفط ووسائط الغاز الطبيعي (وحدة اختيارية مضادة للتآكل للتعامل مع البيئات الحمضية والقلوية)

اختبار خصائص التدفق: الخطية، خطأ التكرار (≤0.1%)، تحليل فقدان الضغط (دقة 0.01 ميجا باسكال)

اختبار الضغط:

اختبار الضغط الثابت 0-40 ميجا باسكال (دقة ± 0.2% FS)، يلبي اختبار قوة غلاف الضغط الاسمي 1.5 مرة واختبار الختم 1.1 مرة (تسرب ≤ 0.01 لتر/دقيقة سائل)

اختبار ضغط النبض (تردد 0-10 هرتز) يحاكي تأثير مطرقة المياه على شبكة الأنابيب ويكتشف عمر إجهاد المعدات

3. القياس الذكي والتحكم وإدارة البيانات

واجهة التشغيل: شاشة تعمل باللمس ملونة مقاس 10 بوصات (1280 × 800)، مفتاح بزر واحد بين الصينية والإنجليزية، مدمج ISO 5167 وAPI 6D وأكثر من 20 قالب اختبار قياسي آخر، وقت ضبط المعلمة أقصر بنسبة 40%

إمكانية تتبع البيانات: تخزين مشفر بسعة 64 جيجابايت + تصدير USB/Ethernet، إنشاء تلقائي لمنحنى التدفق والضغط، مخطط اتجاه التسرب، يدعم برنامج الكمبيوتر العلوي إنشاء تقرير PDF (بما في ذلك تحديد الامتثال)

4. تصميم السلامة والموثوقية

حماية الأجهزة: غرفة الضغط العالي المصنوعة من الفولاذ المقاوم للصدأ (مقاومة الضغط 60 ميجا باسكال) + نافذة مراقبة مقاومة للانفجار (نفاذية الضوء 92٪)، دقة مراقبة التسرب تصل إلى 0.001 لتر / دقيقة

حماية ثلاثية: تفريغ تلقائي للضغط الزائد (قيمة محددة 110%)، إيقاف تشغيل المحرك عند ارتفاع درجة حرارته (>70 درجة مئوية)، زر إيقاف التشغيل في حالات الطوارئ (وقت الاستجابة <0.5 ثانية)، بما يتوافق مع معايير السلامة الكهربائية EN 61010-1

مميزات المنتج

🚀 تثبيت سريع، رفع كهربائي + قفل هوائي، وقت استبدال معدات DN300 أقل من 10 دقائق، متوافق مع الصمامات/عدادات التدفق متعددة العلامات التجارية

🔬 أجهزة استشعار عالية الدقة مستوردة من ألمانيا: تدفق ± 0.3% FS، ضغط ± 0.2% FS، معايرة بواسطة CNAS، تلبي دقة الفئة 1 من ISO 5167

🌐 التوافق القياسي مع إجراءات اختبار API 6D وEN 12266-1 المدمجة، وإنشاء تقارير البيانات المطلوبة للحصول على شهادة CE/API/CCC تلقائيًا

📊 تحليل ذكي إحصائيات SPC في الوقت الفعلي (قيمة CPK/مؤشر قدرة العملية)، والبيانات غير الطبيعية، والتعرف على الذكاء الاصطناعي (دقة 98%)، وإنذار الصوت والضوء

⚙️ توسع مرن وحدة اختيارية لدرجة الحرارة العالية (0-150 درجة مئوية)، نظام فراغ (درجة فراغ ≤10 كيلو باسكال)، تتكيف مع متطلبات اختبار ظروف العمل القاسية

المعايير المرجعية الدولية

معايير قياس التدفق:

معايير اختبار الصمامات:

السلامة والتوافق الكهرومغناطيسي:

| فئة | تفاصيل المعلمة |

| نموذج | دبليو بي تي-7 |

| نطاق اختبار التدفق | 0.1-200 متر مكعب/ساعة (الدقة: ±0.3%FS، مقياس التدفق الكهرومغناطيسي) |

| نطاق اختبار الضغط | 0-40 ميجا باسكال (ضغط ثابت)، 0-25 ميجا باسكال (ضغط النبض) |

| وسائل الاختبار | الماء، الزيت الهيدروليكي، الغاز الطبيعي (طلاء اختياري مضاد للتآكل للأحماض/القلويات) |

| نطاق درجة الحرارة | التشغيل: 0-80 درجة مئوية؛ التخزين: -20-70 درجة مئوية |

| كشف التسرب | السائل: ≤0.01 لتر/دقيقة؛ الغاز: ≤0.1 متر مكعب/ساعة |

| نظام التحكم | PLC + شاشة تعمل باللمس مقاس 10 بوصات (دقة 1280 × 800، ودعم متعدد اللغات) |

| تخزين البيانات | قرص SSD مدمج بسعة 64 جيجابايت (يدعم أكثر من 100000 سجل اختبار، وتصدير عبر USB/Ethernet) |

| حجم منفذ الاختبار | DN25-DN300 (وصلات شفة/ملولبة/ملحومة بطرف) |

| نظام القيادة | محرك سيرفو (القوة: 15 كيلو واط، السرعة: 0-3000 دورة في الدقيقة) |

| فئة الحماية | IP54 (خزانة التحكم)، IP65 (غرفة الاختبار) |

| مزود الطاقة | تيار متردد 380 فولت ± 10%، 50/60 هرتز، الطاقة المقدرة: 25 كيلو واط (الذروة: 35 كيلو واط) |

| أبعاد | 2500×1800×3000 مم (الطول×العرض×الارتفاع، بما في ذلك إطار الدعم) |

| وزن | 2000 كجم (إطار من الفولاذ المقاوم للصدأ + تركيبات من سبائك الألومنيوم) |

| تواصل | RS485/Modbus TCP، USB 3.0، Ethernet (يدعم بروتوكول OPC UA لتكامل MES) |

| مستوى الضوضاء | ≤75 ديسيبل (يتم القياس على مسافة متر واحد، تشغيل بدون تحميل) |

| فئة الخدمة | تفاصيل |

| ضمان | ضمان لمدة عامين على الجهاز بالكامل، وضمان لمدة 5 سنوات لأجهزة الاستشعار وأنظمة المؤازرة، وصيانة مدى الحياة بتكلفة معقولة للمكونات الأساسية (PLC/شاشة اللمس) |

| آلية الاستجابة | دعم فني باللغتين الإنجليزية والصينية على مدار 24 ساعة (المساعدة عبر الهاتف/عن بُعد)، وحلول مخصصة في غضون 48 ساعة، وتسليم خلال 7 أيام للطلبات المحلية |

| خدمات ذات قيمة مضافة | التثبيت المجاني في الموقع وتصحيح الأخطاء (بما في ذلك تدريب ثلاثة موظفين، وعرض إجراءات اختبار معيار ISO/API)، وترقيات البرامج المجانية مدى الحياة، وتوسيع وحدة الأجهزة (على سبيل المثال، مكونات الاختبار ذات درجات الحرارة العالية/الضغط العالي) |

| إمكانية تتبع الجودة | يتم توفير تقارير معايرة المعدات (الصادرة عن مختبرات معتمدة من CNAS)، والتي تدعم الاستعلام عن البيانات التاريخية لمدة 3 سنوات وإمكانية تتبعها |

ساعات العمل لدينا

الإثنين 21/11 - الأربعاء 23/11: 9 صباحًا - 8 مساءً

الخميس 24/11: مغلق - عيد شكر سعيد!

الجمعة 25/11: 8 صباحًا - 10 مساءً

السبت 26/11 - الأحد 27/11: 10 صباحًا - 9 مساءً

(جميع الساعات بالتوقيت الشرقي)